Technology Timeline

A history of innovation in jet grouting technology

-

1969

High-Pressure Jet Injection Method

The Single-Pipe Method was initially developed to overcome the limitations of conventional chemical grouting. High-pressure pumps enabled grout injection and jetting to cut and mix the soil for improved ground strength.

Applications included soil stabilization for excavation, retaining walls, tunnel reinforcement, and more.

-

1970

Development of Jet Mixing Methods

The Double-Pipe Method was introduced to expand improvement diameters. It used an inner pipe for grout and an outer pipe for compressed air. Later, the Triple-Pipe Method added water jets, reducing surrounding soil impact and enabling larger improvements.

-

1993 - 2011

Recent Advancements

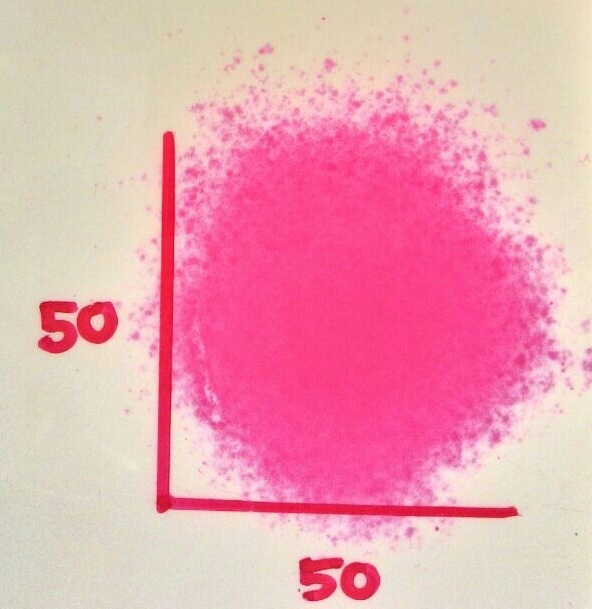

- 1992 - L-Dis Method

- 1993 - Super Jet Method

- 1994 - Cross Jet Method

- 1999 - JEP Method

- 2002 - Separate Jet Method

- 2008 - Multi Jet Method

- 2011 - V-JET Method

-

Join

Our

Innovation!